What does cake moisture mean in this application?

The Filter Plant Calculator allows you to input a value for cake moisture on the Water/Cake tab. It is best that you have established this value from a test programme, or experience with a very similar slurry processed through similar equipment. It then uses this to calculate further useful values, for example:

- the amount of water per hour that goes with the filter cake and how much can be recovered to filtrate (and then potentially returned to the Mineral Process). This also gives a measure of the percentage of water that can be recovered from the slurry.

- the relative volumes of the phases in the cake (solids, water and air). This can be a useful parameter for assessing transportation and deposition.

Below we will look at cake moisture and the derived parameters, noting how they can be determined using the calculator and then, at the end, what they may mean for you.

Below we will look at cake moisture and the derived parameters, noting how they can be determined using the calculator and then, at the end, what they may mean for you.

Definition

The cake moisture is simply the percentage of the cake weight that is water:

Measuring

The moisture can be measured from a laboratory or pilot test perhaps using an oven or, for a quicker result, a moisture balance. It is best to take a number of samples from a number of parts of the cake to check for variations.

How it is used in the calculator

Here we will review quickly a simple case to show how this can be useful.

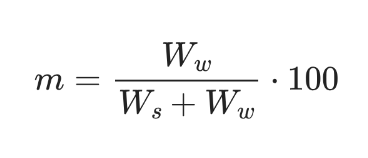

First of all, inputting a typical set of slurry parameters and a throughput of 10,000 tpd (dry solids) into the Process Design Criteria tab:  The important parameter to note here is 56% w/w solids in the feed. This, together with the densities of solids and liquids can be used to calculate the mass and volume flows. Note that our 10,000 tpd solids gives 327.4 tph water in the slurry feed.

The important parameter to note here is 56% w/w solids in the feed. This, together with the densities of solids and liquids can be used to calculate the mass and volume flows. Note that our 10,000 tpd solids gives 327.4 tph water in the slurry feed.

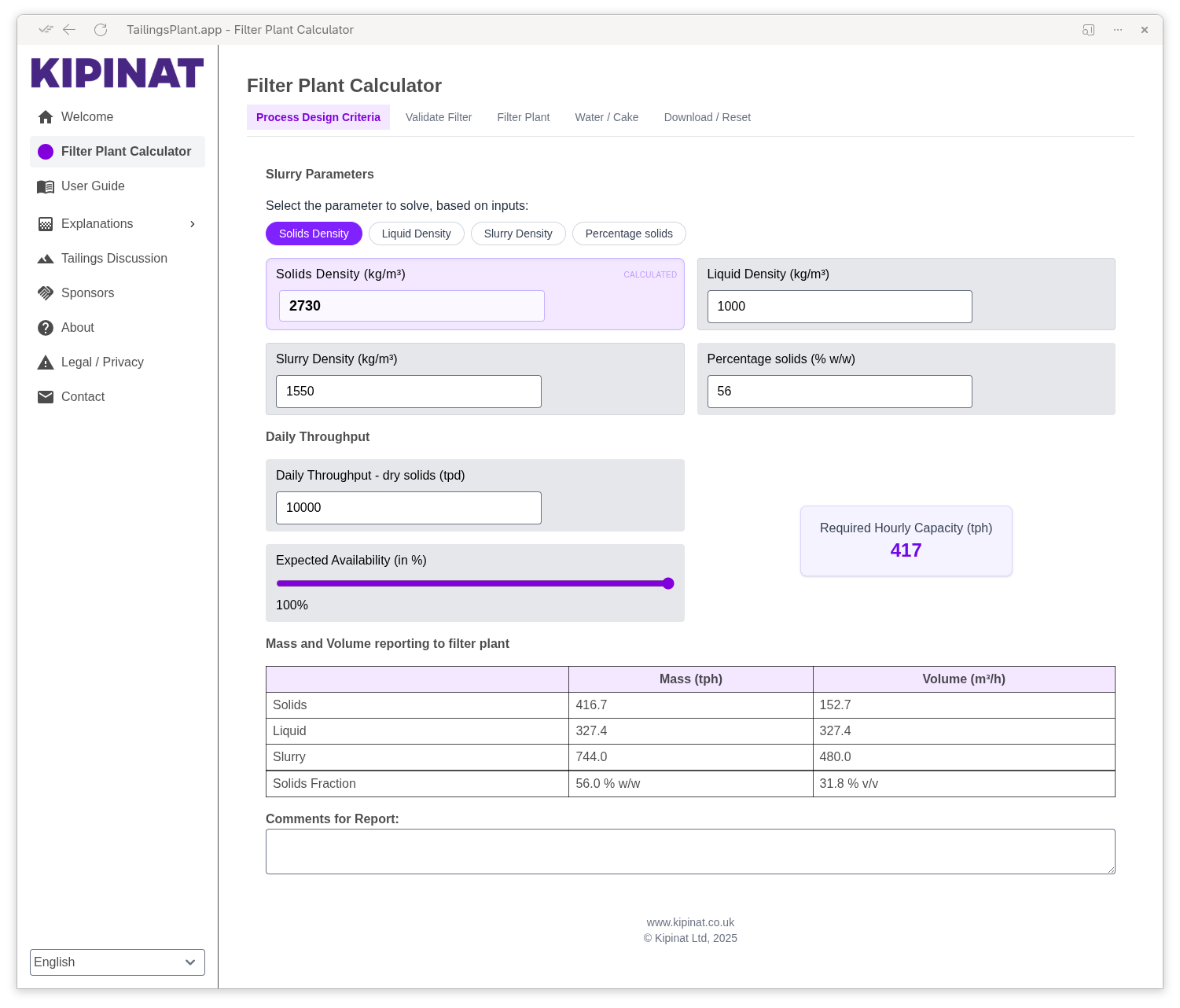

Selecting a filter press as follows (with cake porosity 48 %v/v):  Then, for a cake moisture of 14.2 % we get:

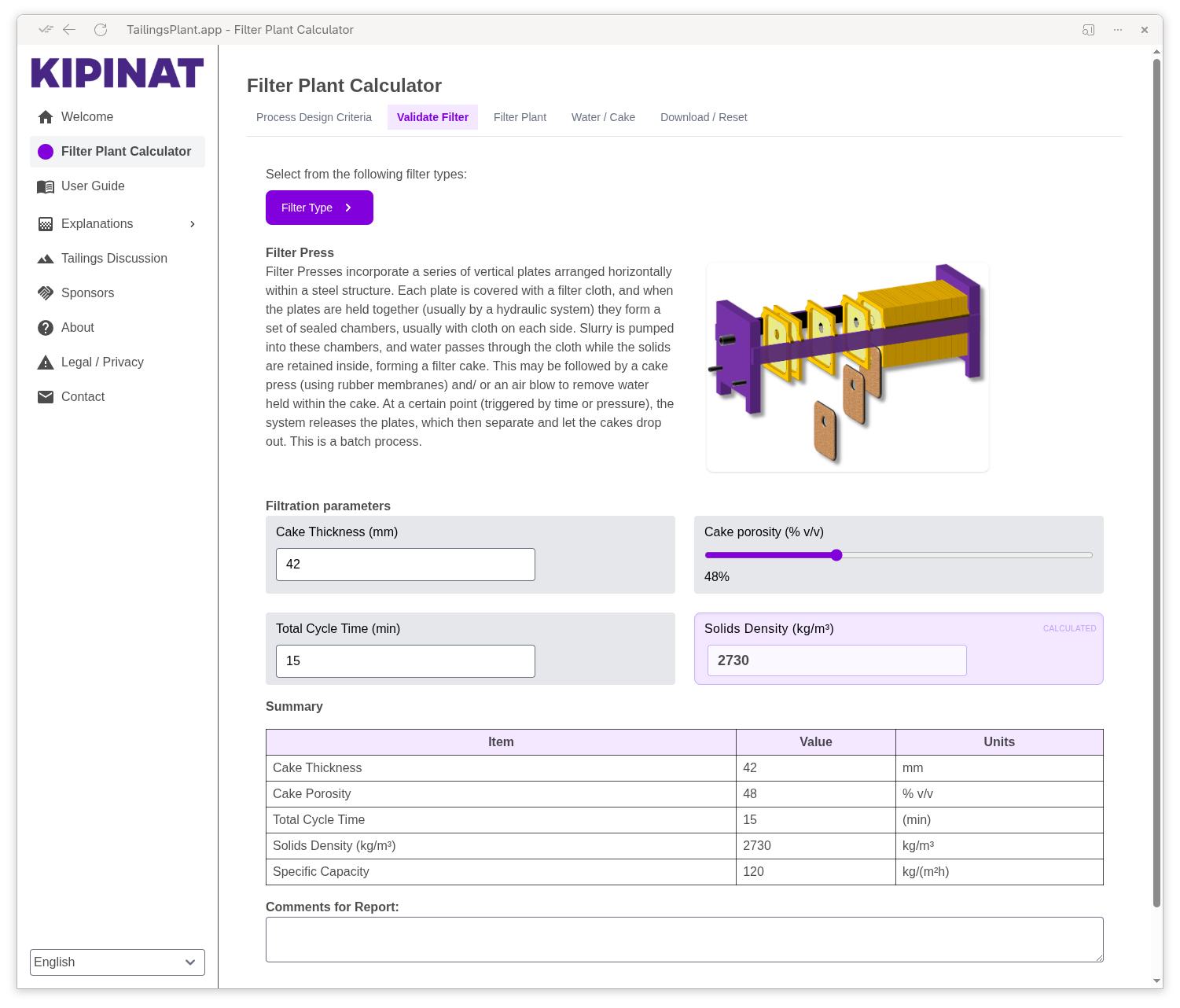

Then, for a cake moisture of 14.2 % we get:  Here, we see a Water Recovery of 78.9 %. It is very important to note that:

Here, we see a Water Recovery of 78.9 %. It is very important to note that:

- This value is referring to the percentage of water in the feed slurry that can arrive in the filtrate tank according to the parameters that you enter. In this case 258.4 from 327.4 tph.

- This value does not take into account any water that is needed to operate the filter plant (for example cloth washing water, filter cleaning & flushing, pump gland water etc.). In this respect it can be considered the Maximum Possible Water Recovery that could be reached. It may, for example, be possible to use filtrate for some of the water needed to operate the plant.

The calculator also provides the Geotechnical Water Content, defined as the percentage by weight of water to solids

here our 14.2 %w/w cake moisture is equivalent to 16.6 % water content.

The table shows the relative volumes of the three phases in the filter cake (solids, water and air - which are also shown in the chart). Finally, the cake bulk density, calculated from these volumes, is shown in the bottom row of the table .

This is the undisturbed filter cake density. Once it has been discharged from the filter the cake pieces will be stacked together with air between them. The bulk density of this cake pile will not be the same as the value in this table.

What next

So, we have been able, quickly and easily, to find some some parameters.

The Maximum Possible Water Recovery can be compared to the recovery of water from a conventional TSF, where losses to evaporation, seepage and retained water will be larger.

Water and Tailings are very strongly related issues. If the mine is located in a very dry or wet region, then recovering water before the Tailings Storage Facility can have an extremely important impact on the success of the operation. Water may be a constraint on your productivity (the amount of ore that you can grind) or your licence(s) to operate. The Water Recovery can enable you to look at how you might lessen these constraints.

Finally the Cake Bulk Density and Cake Phase Volumes are essential when considering how to transport filter cake to tailings storage and how to deposit it.