Dewatering of tailings

Filtration processes have been used in mineral processing since the end of the 19th Century — the photograph below was taken more that 100 years ago and shows a filter press used to produce a transportable kaolin cake in Cornwall, UK, before it was shipped to the North of England.

(Image courtesy of the Wheal Martyn Museum).

(Image courtesy of the Wheal Martyn Museum).

Filtration was mainly used in mining to remove water from mineral concentrate slurries, before shipping to refineries. A refinery may be thousands of kilometers away, and the lives of 70 seafarers were lost in the decade from 2013—2022 because of cargo liquefaction in ships, mainly nickel ore and bauxite (Source: The International Association of Dry Cargo Shipowners, 2023). The Transportable Moisture Limit (TML), which should be determined for each shipment and can vary significantly depend on the mineral properties, is therefore crucial. However, once the ship’s voyage is complete and the concentrate processed, the danger for that batch has passed.

Key differences between concentrate and tailings filtration include:

Mining operations deposit their tailings close to where they were produced, but expect them to remain where they are deposited, forever. Any deviation in filtration performance is therefore permanent and a pocket or layer of deposited filter cake with off-spec characteristics could cause issues many decades later.

The volume of tailings is vastly higher. This is most obvious in the case of low-grade copper, in which the tailings filter plant may have >150 times the filtration throughput compared to the concentrate filters.

Present trends

During recent decades, the dewatering of thickened tailings with filters has become more widely adopted, and can bring significant benefits to the mine operation and local people, communities, nature and landscape:

- extending the lifetime of tailings storage facilities (TSFs) and reducing their footprint

- enhancing water recovery and management

- significantly reducing the probability of tailings facility failure

- reducing the leaching of contaminants from TSFs

- producing filter cake to be blended into paste backfill plants while recovering water.

- removing constraints on production (if the constraints are water use and tailings volume)

Tailings filtration can increase production rates (through water recovery), and extend mine lifetime (through reducing the volume of tailings per tonne of concentrate).

There cannot be a universal Best-Available-Method for tailings management, since:

- all tailings streams are different (in terms of particle size distribution, mineralogy, water quality…)

- every project has a unique context (local climate, seismic activity, nature, communities …)

- regulatory requirements and the owner’s strategy and policies will all influence what methods for tailings management are chosen.

Additionally, developing optimal dewatering flowsheet choices for tailings is a developing practice, but must:

- be an iterative process between Mineral Processing and Geotechnical disciplines (a simplified view of this is that the geotechs say what is needed, and the process engineers say what is possible, and at what cost)

- make maximum use of available samples to determine dewatering and deposited (stability, geochemical) properties in an appropriate testing programme. Small changes in the tailings fed to a dewatering plant could have a profound impact.

The Filtered Stacked Tailings Guide, published by the BHP - Rio Tinto Tailings Management Consortium in 2024 is filled with practical information to support study managers.

Dewatering and filtration choices

Throughout this application, we assume that the slurry reporting to the tailings filtration plant has been pre-thickened, generally to above 55% w/w. (We do not discuss thickening in this application, but it is important to familiarise yourself with this topic.)

Filtration/ dewatering technologies and processes can be categorised according to their:

- main dewatering mechanism

- mode of operation.

Dewatering Mechanisms:

- Pressure — pumping slurry into a filtration device so that filter cakes form on filter media and filtrate recovered after it has passed through the growing filter cake and filter media. This filter cake may then, optionally, be pressed (or consolidated) further and/ or de-liquored by blowing pressurised air through the cakes to drive inter-particle liquid through.

- Vacuum — holding a vacuum behind the filter media, so that atmospheric pressure presses liquid through the filter cake and filter media. This cake may then undergo further de-liquoring as air passes through. Other steps may be taken to remove water further, including vibration of the cake or mechanical squeezing of the cake.

- Gravity — dewatering screens, or in-situ (for example buy placing channels of sand throughout the stack through which water can pass through)

- Centrifugal — generally solid-bowl centrifuges, in which solids settle onto a the inner surface of a rapidly-spinning cylinder, in an acceleration field orders of magnitude stronger than gravity.

- (Evaporation — in hot, low-rainfall, climates it may be possible to allow filter cake that is almost at the required moisture to dry before or during transportation and deposition, perhaps on a pad. This can be enhanced by ploughing, but will result in water loss and extra dust may be an undesired consequence.)

Modes of operation:

A very important consideration is how the filtration process delivers cake:

- Continuously, in which slurry is fed continuously to the dewatering plant when it is operating, and filter cake delivered continuously. A unit delivering 50 tph would discharge ~15 kg/s of filter cake.

- Batch-wise, in which slurry is fed to a machine, processed further and then discharged at the end of the cycle. Such a filter might be closed for 50 minutes per hour, and discharge ~100 to 150 kg/s for a few minutes.

Any one of these technologies can be, and indeed are, used in tailings dewatering processes; however, the following statements are relatively uncontroversial:

- Plants with continuous dewatering machines are generally simpler to build and operate, given that they do not require buffer storage of slurry upstream and cake downstream of the dewatering process while it is running.

- Pressure filtration will generally deliver a lower cake moisture than units that use vacuum, gravity (or centrifugation). In some projects this means that filter presses are the only viable selection that can deliver stackable tailings in one step.

- Equipment and technology is advancing at a pace, particularly in terms of :

- the size and capacity of units

- enhancements to the dewatering mechanism(s) — for example vibration, heat, chemical additives

- there is also ongoing work investigating upstream enhancement and optimisation of the tailings with respect to dewatering.

A tiny cube of tailings filter cake does not know whether it is in a filter press with a plate pack volume of 1 m3 or 50+ 3, it only responds to the flow, compressive forces and flow of air to which it is subjected. This basis of the sizing calculations in this application proceeds are:

- establish the solids density of the tailings

- determine the volume of filter cake per hour, per m2 that a filter can deliver

- (this is based upon the filter cake thickness and a rate — either batch time or speed)

- establish a cake porosity — this can be done with a simple lab test.

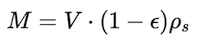

Then the capacity is simply  Where:

Where:

| Symbol | Units | |

|---|---|---|

| M | specific capacity — dry solids per sq. m per hr | kg(m2h)-1 |

| V | volume of filter cake per sq. m per hour | m3(m2h)-1 |

| ε | filter cake porosity | % v/v |

| ⍴s | solids density | kg m-3 |

There is specific information on this capacity calculation for the main filter types given in their respective pages here:

Summary

Tailings can be filtered:

- and bring significant potential benefits, for example:

- reducing risks

- reducing water use, and potentially removing water constraints

- extending the life of TSFs, and potentially, therefore, mines.

- in a variety of different ways, for example:

- continuously or in batches

- pressure or vacuum filtration or gravity/ centrifugal acceleration

- after a careful study and test programme to determine the optimal technology, or combination of technologies.