Pressure Filters

Filter Presses have been used for almost 150 years and are well-proven see Dewatering of tailings. In recent decades, mostly because of tailings dewatering, they have become larger, much larger. They offer the highest dewatering power concentration of all of the units in this calculator, and therefore, frequently produce the driest filter cake for deposition. Filter cake from an individual unit is delivered in batches, so a unit may be closed for, say, 10 minutes, and then a large amount of cake discharged in a very short time. In the case of filter plants with a number of units, cake delivery to the TSF can be smoothed by sequencing the filters’ cycles and keeping some cake buffer capacity.

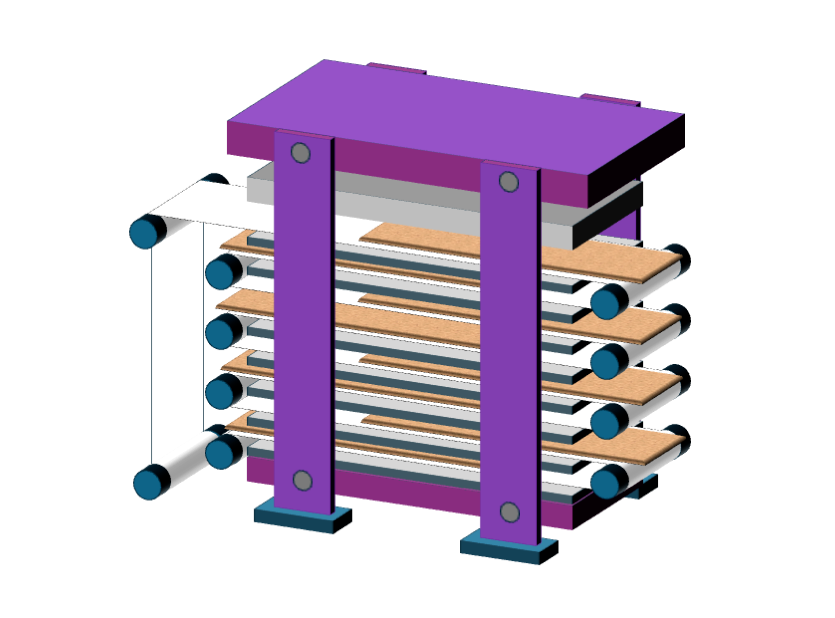

Filter presses comprise three main elements:

- A pack of filter plates that form a set of chambers when pushed together. Each chamber normally has cloth covering both sides. In operation, the pack of plates is squeezed together, to form a number of filtration chambers, each containing a filtration surface. The plate pack may also incorporate diaphragms that can be pressurised to squeeze the cake and remove more water (they can also remain pressurised to hold the filter cake and resist cake cracking during air-blowing)

- A frame, or structure, that can hold this plate pack closed and resist forces resulting from the pressure used for dewatering process.

- A system for the opening and closing of the plate pack, cake discharge, cleaning etc.

In operation

- Slurry Feeding A pump delivers slurry to each individual chamber and filtrate passes through the cloth, as filter cake builds on the filter cloths

- Cake pressing (optional) Pressurized fluid, usually air, can be passed to diaphragms in each of the chambers so that they press the cake. This pressing, normally at up to 16 bar

- Air drying Compressed air passes through the filter cakes, but it is possible to pass air through the cake while it is still being pressed.

- Cake Discharge Once the filtration process steps have finished, the plate pack will open (driven by the hydraulic cylinder). The plates pack can open all at once, or in smaller groups (perhaps one at a time). Filter cakes in tailings filter applications are extremely large, and heavy. Given that the cake discharge will be intermittent, the cake handling system must be designed to cope with large amounts of cake from time to time and would be more substantial than a cake handling system for a continuous filter with the same daily throughput.

Key parameters for the specific throughput of a pressure filter (kg(m2h)-1) are:

- Volume of cake per cycle, which we establish from the Cake Thickness

- Cake Porosity, from which we can find the percentage volume that is solid

- Solids Density

- Cycle Time, which is the sum of the time taken for all of the stages in the list above, plus an allowance for the mechanical operations of the filter (closing, de-pressurising, cleaning, valve operations etc.), the Technical Time. Here you should consult with an experienced professional or engage with vendors. In general, the Technical Time can range from 4 minutes to around 15 minutes, depending upon the slurry, machine, conditions etc.

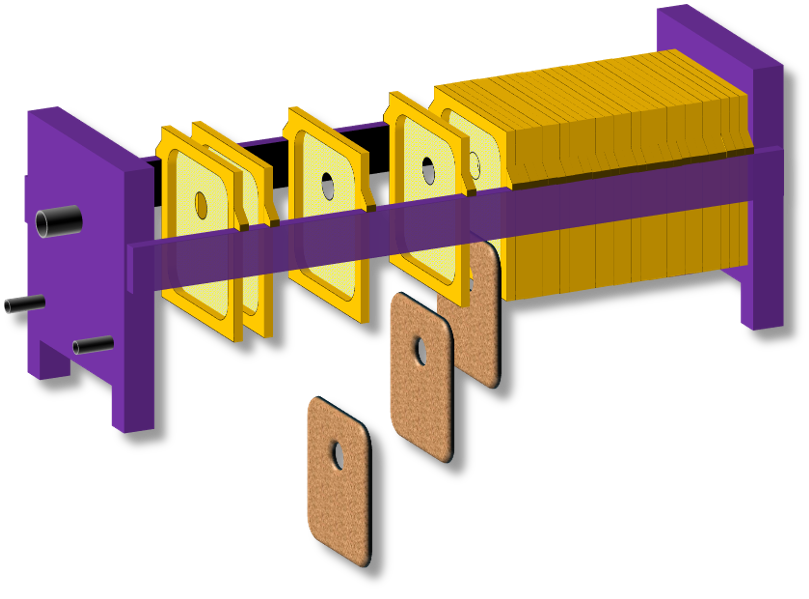

(Tower Press filters)

Tower press filters are a variant of Filter Presses. The main differences are (i) the filter plates that form a set of chambers when closed are arranged horizontally, rather that vertically (ii) a cloth, serving as both filter medium and cake discharge conveyor ia arranged through the plate pack, over rollers at the end of each plate. While are a number of benefits to this approach, their application to tailings dewatering is limited by their size (the largest have a filtration area ~150 m²).  The difference when sizing a Tower Press filter and a Filter Press is mainly in the filter cloth area. A Tower Press chamber (usually) has filter cloth on the bottom only, whereas a Filter Press chamber (usually) has filter cloth on both sides. So, if the Cake Thickness, Total Cycle Time, Cake Porosity and Solids Density were the same, the Filter Press capacity per m2 would be 50 % of that for the Tower Press.

The difference when sizing a Tower Press filter and a Filter Press is mainly in the filter cloth area. A Tower Press chamber (usually) has filter cloth on the bottom only, whereas a Filter Press chamber (usually) has filter cloth on both sides. So, if the Cake Thickness, Total Cycle Time, Cake Porosity and Solids Density were the same, the Filter Press capacity per m2 would be 50 % of that for the Tower Press.

Testing

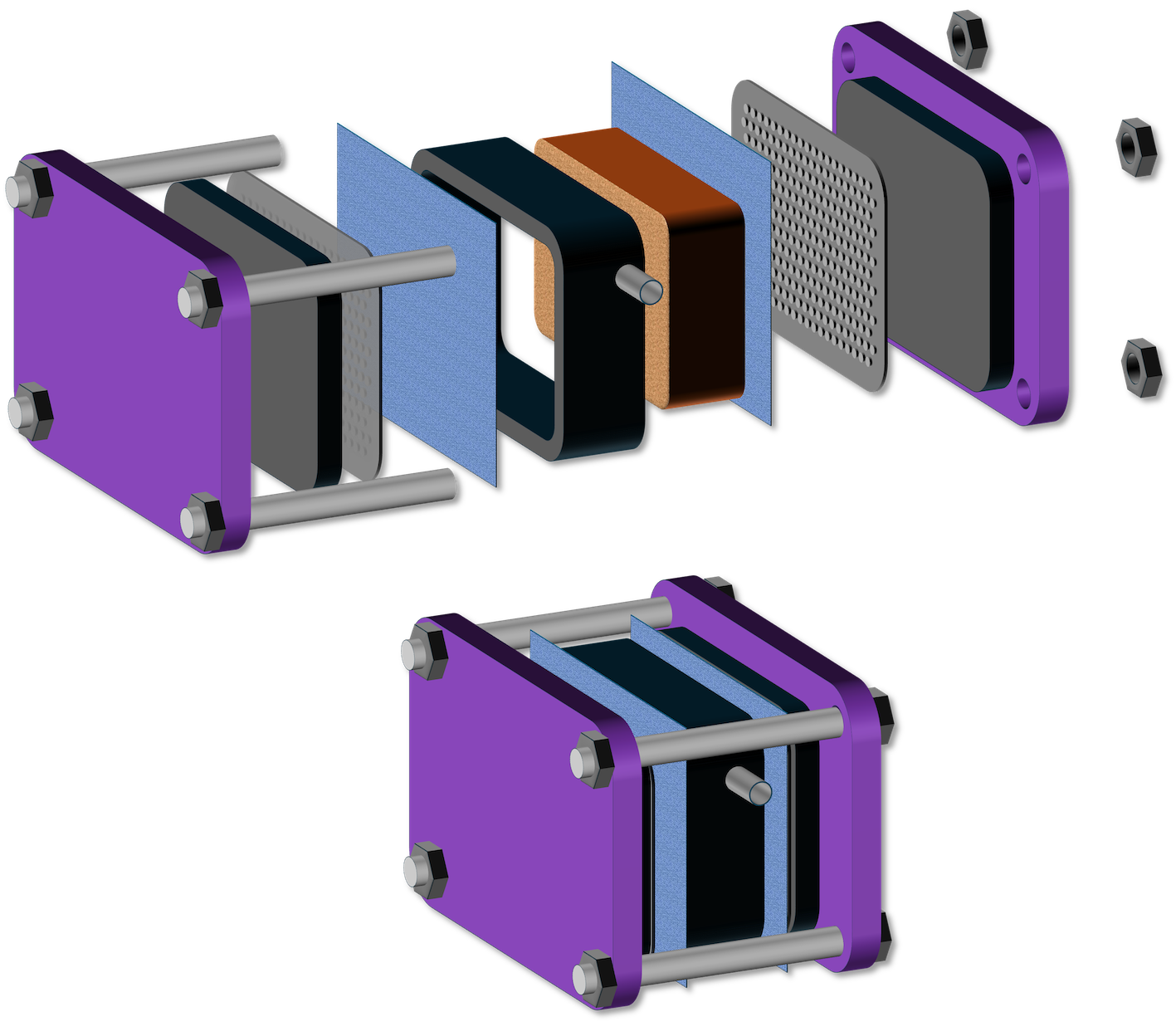

A general pressure testing device, such as that shown in Parameters - slurry can be used to establish a good indication of the parameters needed for calculating a specific capacity.

Other units, such as that shown below, can allow the user to include a cake pressing stage in the test. Such units include (for example) from left to right in the image below:

- a pressure plates to withstand the forces from the process, this incorporated bolted bars

- a drainage plate to allow filtrate (and drying air) to pass

- an optional rubber membrane for cake pressing

- a cloth

- a chamber section

- (filter cake produced)

- then the components repeat and finally bolts hold the whole assembly together.

The units, when assembled can be used to mimic the overall operation of a filter press.

Worked example

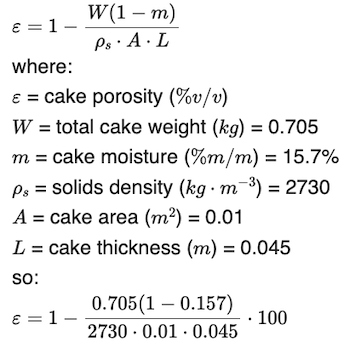

You have performed a test, producing a 45 mm thick cake with a combined feeding, pressing and air drying time of 5.2 minutes. The cake weighs 705 g, contains 15.7 % w/w moisture and the face area of the cake was 0.01 m2.

Using the method in Parameters - slurry, you can calculate the porosity:  So the Cake Porosity is 48.4% v/v (round down to 48% v/v). After speaking with your favoured filter vendor, you agree to add 7 minutes to the cycle time, giving a total of 12.2 minutes.

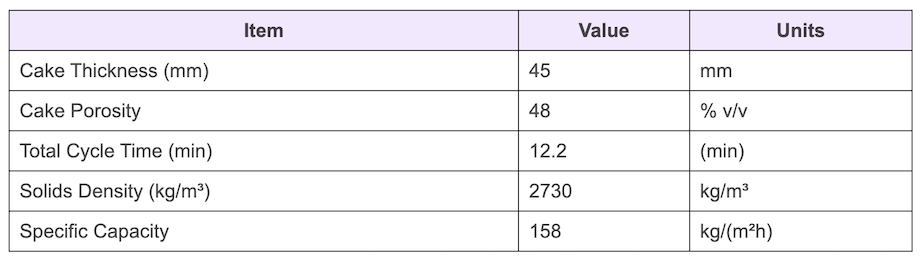

Then, selecting Filter Press filter in the Validate Filter tab of the Filter Plant Calculator, you input these values, to get the following result:

So the Cake Porosity is 48.4% v/v (round down to 48% v/v). After speaking with your favoured filter vendor, you agree to add 7 minutes to the cycle time, giving a total of 12.2 minutes.

Then, selecting Filter Press filter in the Validate Filter tab of the Filter Plant Calculator, you input these values, to get the following result: