Parameters - Slurry

This calculator can be used with input parameters that you can base on expert advice, previous experience or assume. However, it is vital that you undertake simple tests, as soon as you have sample available. There is no substitute for making filter cakes in representative test equipment under representative conditions.

Slurry Parameters

On the Process Design Criteria tab you can establish the main slurry parameters. You may already have them, and this tab can be a useful way to check.

Normally it is quite simple to measure the slurry density and liquid density by measuring the weight of a fixed volume (the liquid could be filtrate or clear liquid from a settling test). It is also simple to find the percentage solids by weight (% w/w).

This means that solids density is often the unknown. Providing that the care is taken with the samples, this procedure will give good results for the later tests.

Two of the parameters from this tab will be used later in the calculator:

- the solids density is used in the calculation to establish the specific capacity (throughput per m²) of the filter.

- Percentage solids will be used to look at the possible water recovery from the filtration step.

Obtaining Parameters for filtration testing.

Objectives

- obtain useful parameters SAFELY

- always follow the operating manual for the test equipment that you are using, assess all potential risks and take care with your work.

- establish the specific capacity of a filter device.

- measure filter cake moisture.

Prerequisite

- A slurry sample.

- This should be as representative as possible, for example a range of samples from an existing operation, or a thickened sample obtained from flotation trials for a new project.

- The density of the solids in your slurry.

- This may be from a gravimetric test, using a pycnometer or from a reference.

- A test filter. This can be either:

- a general unit that can provide a good indication of the filtration characteristics of your slurry, or

- a unit that is designed to simulate the performance of a specific type of filter.

- General laboratory equipment and instruments, e.g.:

- weighing scales (a moisture-measuring balance)

- sample bottles

- stopwatch

- drying oven

General test procedure

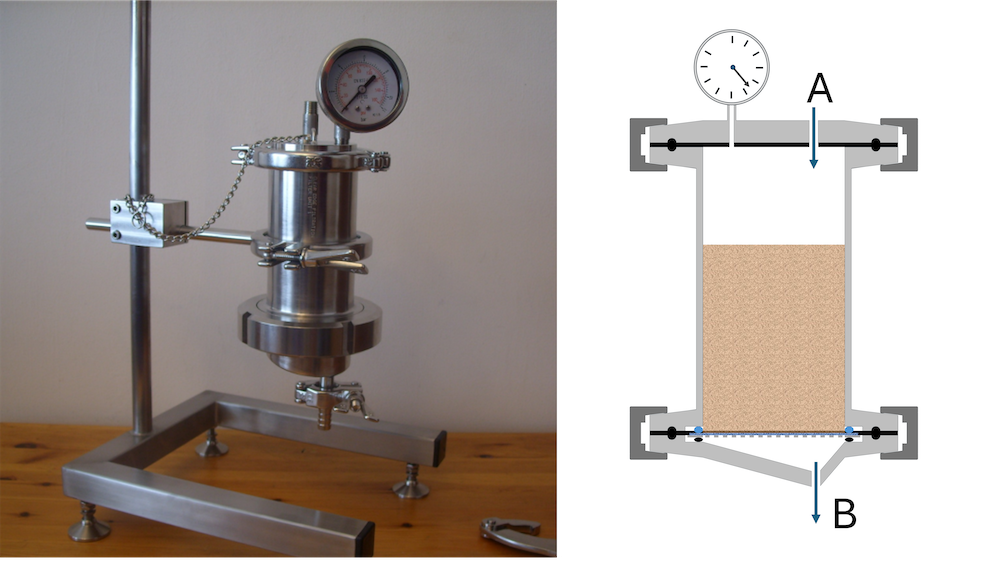

Below is an example of a general test filter. This unit is a simple closed pipe with a filter cloth in its base and, after the pipe is closed, pressurised air can be used to drive the filtration process. Units like this are extremely useful in finding general filtration parameters for a particular slurry  Tests can be performed by:

Tests can be performed by:

- opening the unit

- filling it with slurry from the top

- closing and securing the unit

- applying over pressure, from compressed air supply through the top (Input A)

- collecting the filtrate that emerges from Outlet B.

To gain an indication of performance for a vacuum filter (belt or disc), limit the over pressure to ~0.6 bar. For pressure filtration, you might use a pressure of 6 or 7 bar.

Test units designed for specific filter type are discussed in their own section:

Outline procedure

Filter capacity

This is conventionally expressed in kg/(m² h⁻¹). Our approach is to:

- establish the volume of filter cake that a filter will produce per hour

- determine the porosity of this cake - this is the percentage volume of that cake that is not solid — and hence the volume per hour of solids

- multiply this volume by the solids density to obtain the capacity.

For this, we need three important, but easily obtained, cake properties

- porosity

- thickness

- a measure of the time needed for filtration

This will allow us to determine how much filtration area will be needed to process the required throughput.

Objective 2. To establish cake moisture.

This will help later to:

- produce an overall water balance, including the maximum possible water recovery

- feed into the geotechnical design of the TSF

Throughout testing, whether done in-house or by a third party it is vital to keep good records and to test a variety of conditions (for example, testing at 60% w/w solids in feed will tend to give the best results, but in operation what if your plant receives feed at 53% w/w?).

We assume that you have fixed the slurry parameters.

Porosity (% v/v)

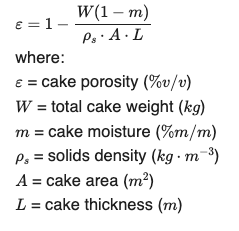

A simple, and sufficiently accurate, method for finding the filter cake porosity, ε, from test work is:

- to take a sample of cake and find its volume and total mass

- It is often simple to take the whole cake, in which case the volume is simply: L・A

- Find the cake moisture, expressed as a total water divided by total cake

- you might do this by weighing before and after drying in an oven, for example

- then:

Worked example

- You are using a general test filter, similar to the unit above, with a diameter of 8 cm

- the solids density, 𝜌s is 2800 kg/m³, the liquid is water at room temperature and slurry percentage solids is 55% w/w, so this is a representative sample

- in the first test the unit is filled with 265 ml of slurry

- the overpressure was set to 0.65 bar

- the flow of filtrate was steady and, after 40 seconds, air started to flow, together with some liquid from Outlet B.

- after 75 seconds the test was ended, the compressed air disconnected and, after venting, the filter opened

- the cake thickness was 40 mm

- (all filter cakes are somewhat compressible, so this thickness may be slightly different to the actual thickness while under pressure)

- filter cakes may also shrink as water is pushed out of the pores, so it can be very useful to also try to produce un-drained cakes for comparison.

- after removal as a whole puck, the cake weighed 281.5 g

- after drying in an oven overnight, the cake weighed 224.8 g

Establish reasonable estimates for:

- the filter cake moisture (% w/w)

- filter cake porosity (% v/v)

- the capacity, in kg/(m²h)

Filter cake moisture

- The cake contains 56.7 g of water, so the filter cake moisture = 20.1 % w/w

- (the geotechnical water content is 25.22%)

Filter cake porosity

- The volume of the filter cake is 201.1 × 10⁻⁶ m³.

- The volume of solids in this cake is 80.4 × 10⁻⁶ m³

- Therefore the filter cake porosity = 60 % v/v

Filter capacity

- Use the Filter Plant Calculator, on the Validate Filter tab enter the following parameters:

- Cake thickness: 40 mm

- Cake porosity: 60 % w/w

- Forming/ Drying time: 75 s

- The calculated specific capacity = 2151 kg/(m²h)