Belt Filters

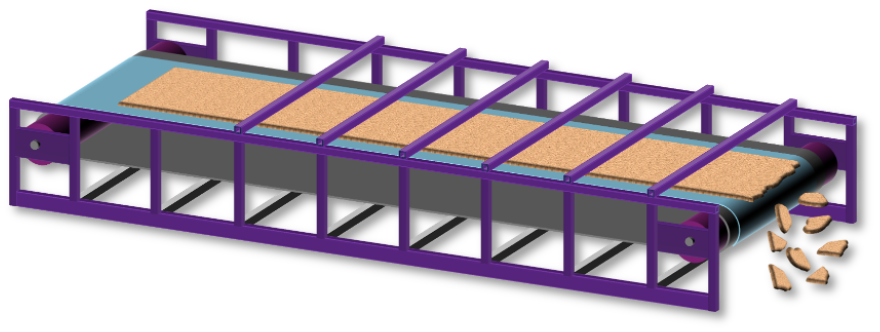

Belt filters consist of a closed-loop grooved rubber belt passing over rollers that acts as a cloth support, filtrate collector and conveyor. Vacuum is the dewatering mechanism, the belt moves at a steady speed, and cake production from the end of the belt is continuous.

Generally, the belt runs along a vacuum box, this arrangement must be lubricated (usually with water). The consumption of this water can be a significant cost factor.

Considering the path of a small piece of slurry:

- Cake formation Slurry pours continuously onto the cloth at the beginning of the belt, vacuum draws liquid through the filter cloth and a filter cake begins to form.

- Cake draining/ drying At a certain point along the belt, the surface of this filter cake begins to dry, as the liquid level drops below the top level of the cake. After further progress along the belt, air will begin to pass through the cake, displacing liquid and drying the cake further.

- Cake Discharge At the end of the filter, cake falls as the cloth and belt pass over the discharge roller. This may be helped with a scraper arrangement.

Filter media

The closed-loop filter cloth can be cleaned as it passes a fixed washing station (usually high pressure spray-bars) during its path from the discharge roller back to the slurry feed end. This cleaning can be continuous, occasional or even controlled automatically.

The dirty water from cloth washing can also be passed onto the cake to minimise the loss of solids material from the process.

Testing

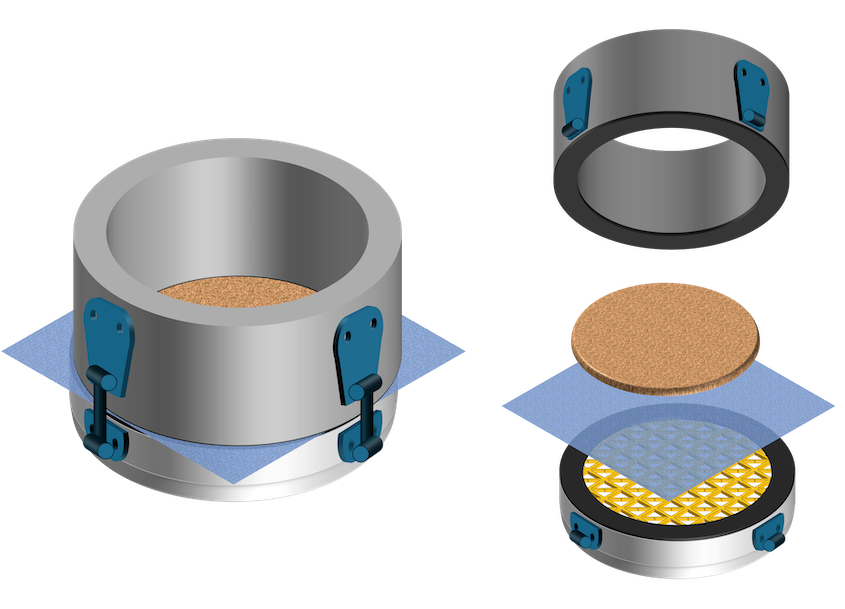

It is quite simple to use a bench-scale unit to obtain parameters for the Filter Plant Calculator using a device similar to that below (sometimes called a Büchner filter):

In it there are, starting from the bottom:

- a base that can connect to a vacuum system (for example sitting on top of a conical flask)

- a support grid in this base, which will allow filtrate to flow freely

- a filter cloth

- a cylindrical collar into which you pour slurry

A valid testing process would be as follows:

- Assemble the test unit and mount onto a vacuum system

- check the vacuum level. 50 kPa would be a sensible value to start with

- Pour well-suspended slurry into the filter and start a timer

- Note the time when the surface of the filter cake becomes dry

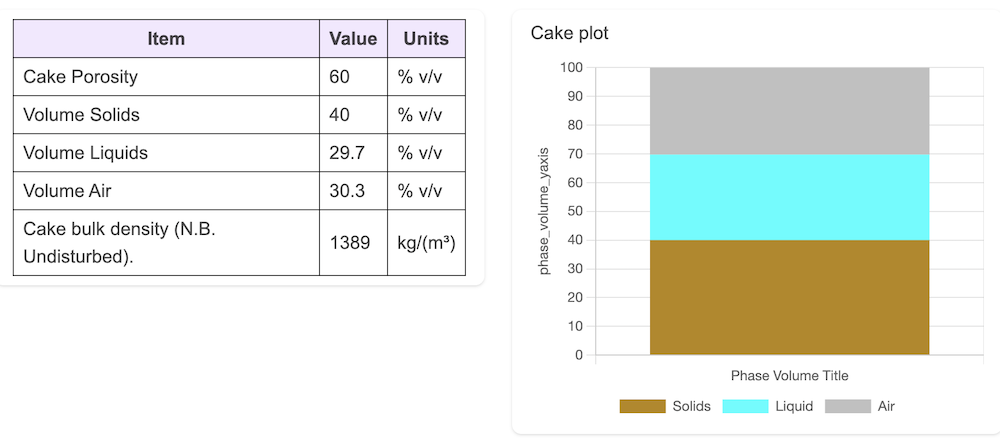

- (it can also be very useful to lay a piece of food-wrap onto the surface of the slurry so that no air can pass through the cake. Then, if you measure the cake thickness and cake moisture you can use this information to compare with the cake phase volume chart in the Water/ Cake tab, this can be a useful quality check for the Cake porosity value that you use)

- When the flow of filtrate has slowed, note the total time.

When you are pouring the slurry, take care to ensure that this is uniform.

Worked Example

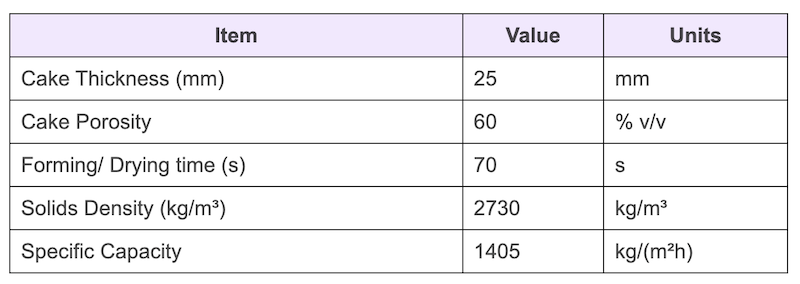

Using a Büchner test filter, you obtain the following results, for a vacuum setting of 50 kPa:

- 25 mm Cake Thickess

- (this also was very uniform and did not have obvious cake cracking).

- 70 seconds Forming/ Drying time

- 21.4% w/w Cake moisture

- 60% v/v Cake porosity

- (see Explanations -> Parameters - Slurry) of 60% v/v.

- Solids Density was found to be 2730 kg m-3.

Inputting parameters from above into the Validate Filter tab of the Filter Plant Calculator:  .

.

Then, on the Water/ Cake tab, using the cake moisture above:  .

.